Method

Inspection of heat exchangers

Dacon Services AS performs cleaning and inspection of heat exchangers.

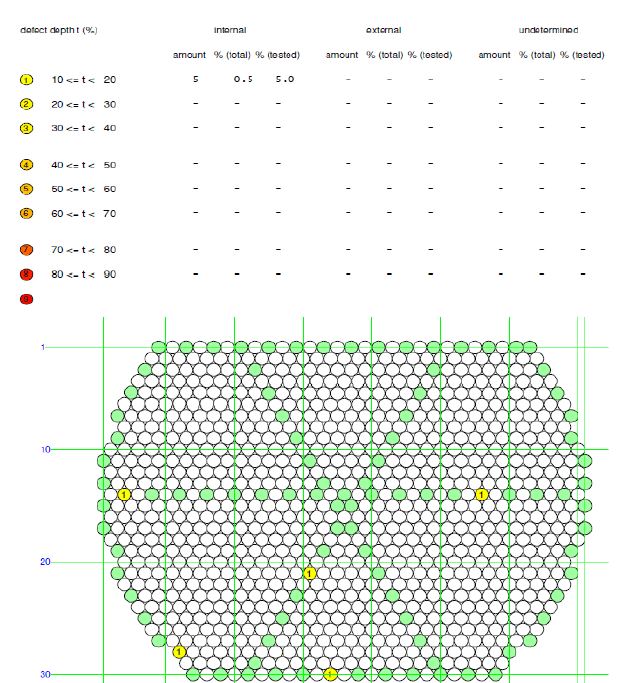

The inspection method is customized based on the customer’s request. Dacon Services AS is certified to perform inspections using NDT-methods such as ET (Eddy Current Testing), MFL (Magnetic Flux Leakage) and video inspection on heat exchangers.

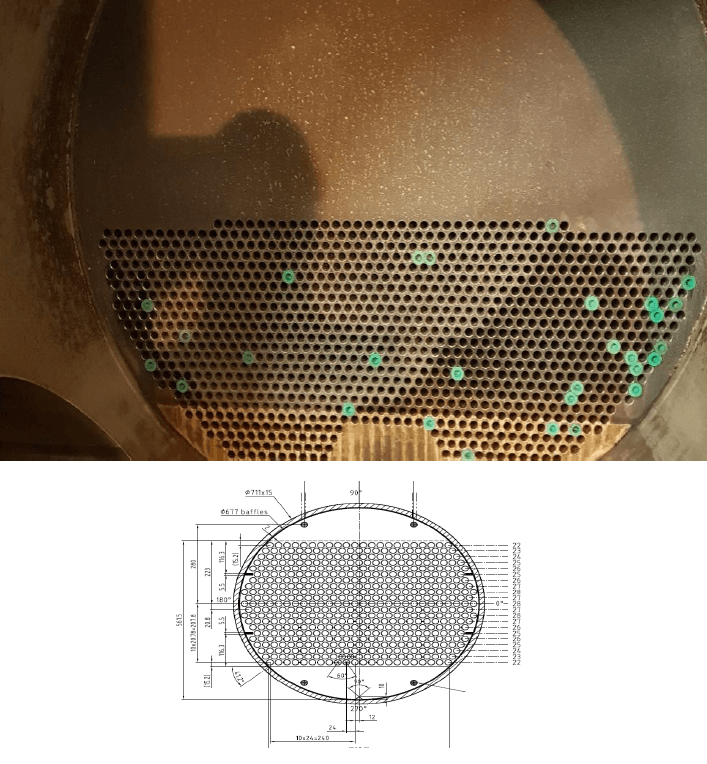

Cleaning and Inspection of heat exchangers

The surface condition of the tubewalls are uncovered by the use of special customized video probes (corrosion, blockages, leakages, etc). Dacon Services AS cleans blocked tube walls using high pressure flushing.

By the use of the ET (Eddy-Current Testing) equipment Ectane 2, Dacon Services AS has the capability to detect a number of faults in the heat exchanger tubes. The apparatus can we equpped with different probes based on the materials to be investigated.

IRIS is an ultrasonic-based method that can detect internal and external corrosion, material thickness, pittings and cracks. The method requires a supply of water.

Dacon Services AS has carried out a number of jobs requiring a combination of both cleaning and inspection of heat exchangers.