Service

Tank inspection

Performed according to API 653.

Dacon Services AS performs complete inspection of industry tanks by the use of our Silverwing Scanner and UT-methods

Tankfloors are scanned by the use of our Silverwing Scanner, and the outside of tanks are scanned by the use of UT and MFL-methods

We use rope access certified personnel for access to tank-walls

Silverwing Floormap Scanner (MFL):

This tank floor inspection system combines two technologies: Magnetic Flux Leakage (MFL) and STARS.

Enables identification of corrosion over/under tank plates at speeds up to 1m/s.

The device is high resoluted and can detect indications down to 2mm (0.08mm in diameter).

Capable of scanning 1400m2 per day.

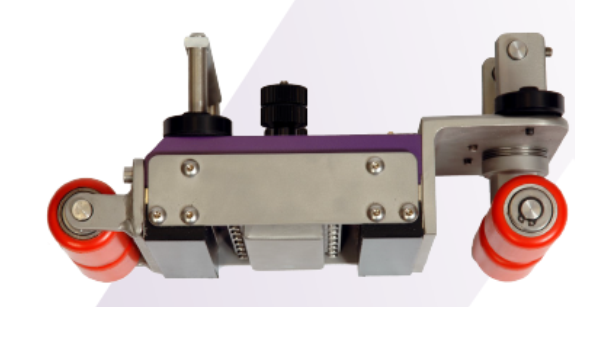

Silverwing hand scanner (MFL):

Enables corrosion identification at speeds up to 0.5m / s.

Maximum thickness of inspection object: 15mm

Can be used through coating thicknesses up to 10mm.

Can be operated from hand on tank walls and can be used on rope access inspection.

We also perform conventional ultrasound measurement using ultrasonic probes and possibly ultrasonic crawler.